Customized High Hardness Wear Resistant Parts Ring by Sand Casting in Stainless Steel

Description

Basic Info.

| Model NO. | Wear Resistant Parts |

| Surface Treatment | Sand Blast |

| Surface Roughness | Ra3.2 |

| Standard | ANSI |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Surface Treatment for | Powder Coating, Painting, Sand Blasting |

| Types of Welding Parts | OEM/ODM |

| Tolerance | 0.01-0.02mm |

| Scrap Rate | 0.5~1% |

| Transport Package | According to The Customers′ Requirement |

| Specification | according to the drawings |

| Trademark | ZLT |

| Origin | Zibo, Shandong Province, China |

| HS Code | 84139100 |

| Production Capacity | 500-1000 PCS Per Month |

Product Description

Brief Introduction:Welcome to Zibo ZLT International who was established in 2006, and Graded as TOP A company in Chinese Customs Classification Management which means the highest reputation and trustful company for exporting, and whose factory is ZIBO QINGDONG MACHINERY MANUFACTURING CO., LTD specialized in castings and machining parts according to customers'drawings or samples in Zibo City, Shandong Province, China.

The castings are mainly made by Lost wax casting, Sand casting, Lost foam casting with the material stainless steel, carbon steel, alloy steel, iron and so on.

The machining parts can be made in our own machining shop. Many advanced equipments such as CNC lathe, CNC cutting machine, miller and so on controlled by experienced workers and extremely strict inspection that will absolutely ensure the high quality products released from our company.

Product Info.| Product | Customized High Hardness Wear Resistant Parts Ring by Sand Casting in Stainless Steel |

| Material | SS316, SS304, CD4,Tianium |

| Manufacturing process | sand casting |

| Certificate | BV certificate, ISO 9001:2008 |

| Weight range | 10 grams by lost wax casting, the largest weight can be made up to 10t/pc or as per customer ' s requirements |

| Payment terms | T/T, L/C |

| Machining | CNC Lathe, Universal Lathe, CNC Cutting Machine, Dynamic Balancing Machine |

| Testing | hydro test, dynamic balancing, hardness test, ultrasonic test etc. |

| Process | moulding pouring machining testing |

| Annual Capacity | The maximum production capacity could be 10, 000 tons per year, with a single piece up to 100 tons, the smallest part only a few grams by lost wax casting, the largest weight can be made up to 10t/pc. |

| Size | As per 100% drawing |

Processing

| Process | Material | |

| Investment casting | waterglass bonded | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass |

| silicon colloidal | ||

| Sand casting | silicate bonded sand | Grey Iron, Ductile Iron, Malleable Iron, Stanless Steel, Carbon, Steel, Brass, Bronze |

| resin sand | ||

| composite shell | ||

| Forging | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass |

| Die Forging | ||

| Roll Forging | ||

| Machining | CNC Lathe,CNC cutting | All material |

| Stamping | Stamping | All material |

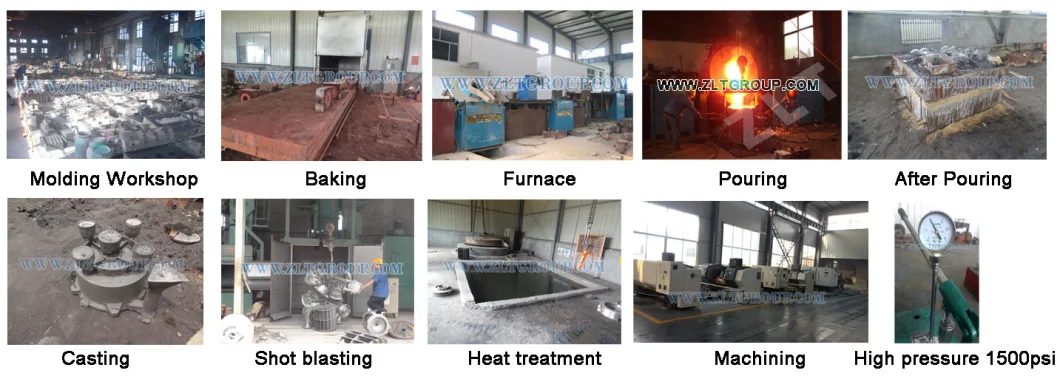

Manufacture Craft:

| Caft | Clarify | Process | Material |

| Lost Wax Casting | silicon colloidal | moulding | Stainless steel, carbon steel, titanium alloy, high chrome, cast iron, bronze, ductile iron brass, etc. |

| pouring | |||

| waterglass bonded | machining | ||

| testing | |||

| Sand Casting | resin sand craft | moulding | Stainless steel, carbon steel, titanium alloy, high chrome, cast iron, bronze, ductile iron brass, etc. |

| pouring | |||

| silicate bonded sand craft | machining | ||

| testing | |||

| composite shell | |||

| Lost Foam Casting | moulding | Stainless steel, carbon steel, titanium alloy, high chrome, cast iron, bronze, ductile iron brass, etc. | |

| pouring | |||

| machining | |||

| testing |

Manufacture Process Pictures:

Equipment and Testing:

Certificate:

Exhibition:

Packing Methods:

| Packing Methods | |||||||||

| Small part, single packed then put into paper carton then to crate. | |||||||||

| 1. Generally use poly wooden crates for package. | |||||||||

| Minimum poly wooden board thickness: 20mm | |||||||||

| Steel band: 19× 0.5mm or 15× 0.5mm | |||||||||

| Common crate size is less than 1200X1000X1000mm | |||||||||

| 2. For the very big part, use welding steel crate. The size and steel thickness is according to the product dimension and weight. | |||||||||

| 3. Large size and large quantity part, put into container directly. | |||||||||

| 4. We also consider customers' special needs for packing |

Contacts:

Zibo ZLT International Trade Co., LtdZibo Qingdong Machinery Manufacturing Co.,Ltd Add: No.7 Zhangzhou Road, Zibo, Shandong, ChinaWeb: http://zltgroup.en.made-in-china.com

Our Contact